My friend explains to me that La Vâltori is kind of like a natural washing machine, and I am lost but intrigued enough to agree to visit. We are in the beautiful Transylvanian countryside, the sun is out, and when we arrive, the only way I know we’re in the right spot is a faded paper posted behind glass in a wooden display sign in the parking area. After poking around a little, a woman from a nearby garden speaks with my friend in Romanian. We meet the family dog (Ela) and the young son while she walks us to the contraption.

Vâltori is the Romanian word for “Vortex”, and that makes sense when you watch the water movement in the barrels. But let’s start at the beginning. The enterprise has been in the family for many generations; one of their forbears invented an underwater barrel that, fed with a water stream from above, created a vortex-like movement (akin to a top-loaded washing machine) and also introduced oxygen into the water. This water movement is used to wash sheep skins and rugs in a natural way without any additions of soap or chemicals; the rug or sheep skin is loaded into the barrel, and after a few hours, it comes out clean. The method has been in use for about 200 years, I believe. They used to have more of the vâltori’s to fulfill the needs of the community, and now the family still has two functional “washing machines” left where they wash people’s rugs and sheep skins on demand. We see a lot of rugs (oriental and otherwise) and some sheep skins either waiting to be washed, hanging to dry, or clean and waiting to be picked up. I think this is a cool concept, and soon I find out how inventive this family really was.

You see on the photo below their home-made sheep skin combing machine. After the sheep skins are washed, they are fixed onto a rotating horizontal cylinder skeleton, which turns endlessly, running on the adjacent stream’s power; no electricity is needed here. The cylinder slaps the sheep skin down onto the floor where it’s dragged across a comb created by nails. This makes the fur of the sheep skin soft. After this treatment is complete, the sheep skin goes into the “sauna” where it is placed inside a tubular skeleton like the combing machine and gets tossed about inside a high-heat room. This process seals the sheep skin and makes it durable without the need of any chemicals. I couldn’t get a good photo of this through the glass window and it moving rapidly. I also see a loom with the beginning of a rug as well as as an old sewing machine and an old spinning wheel.

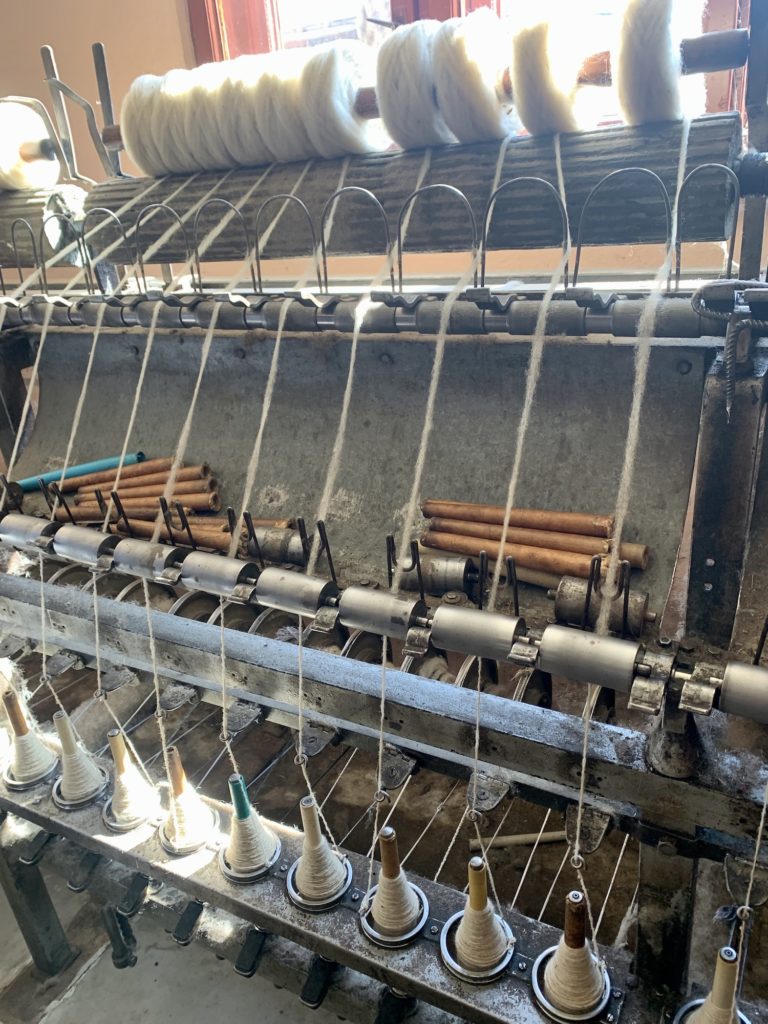

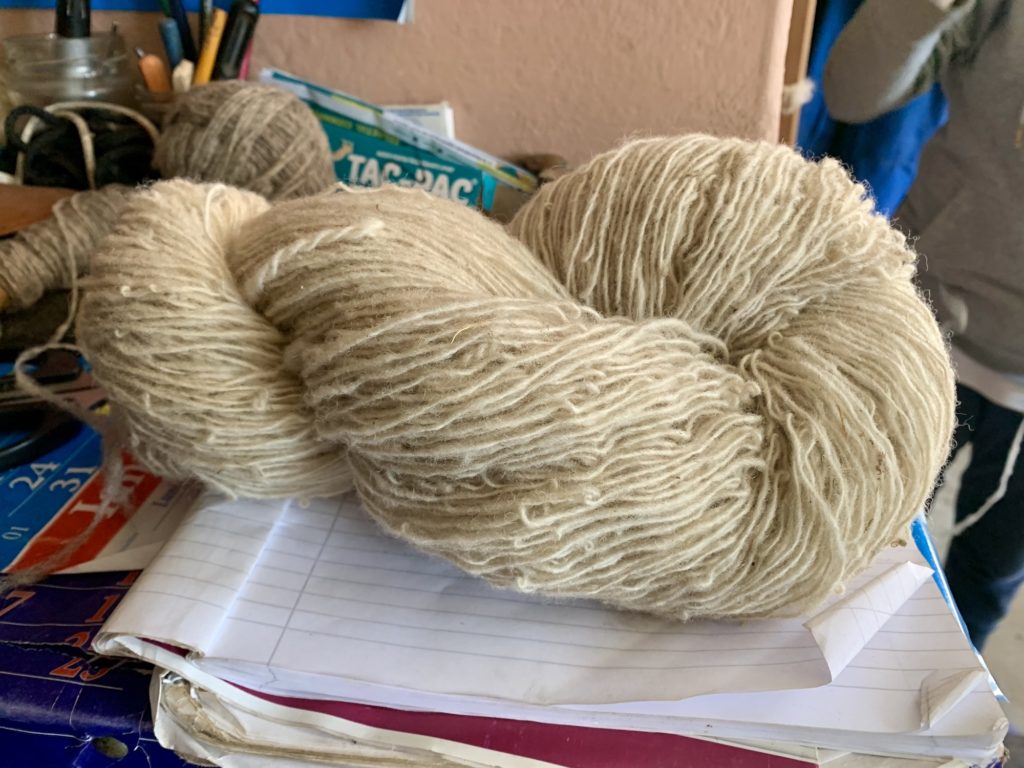

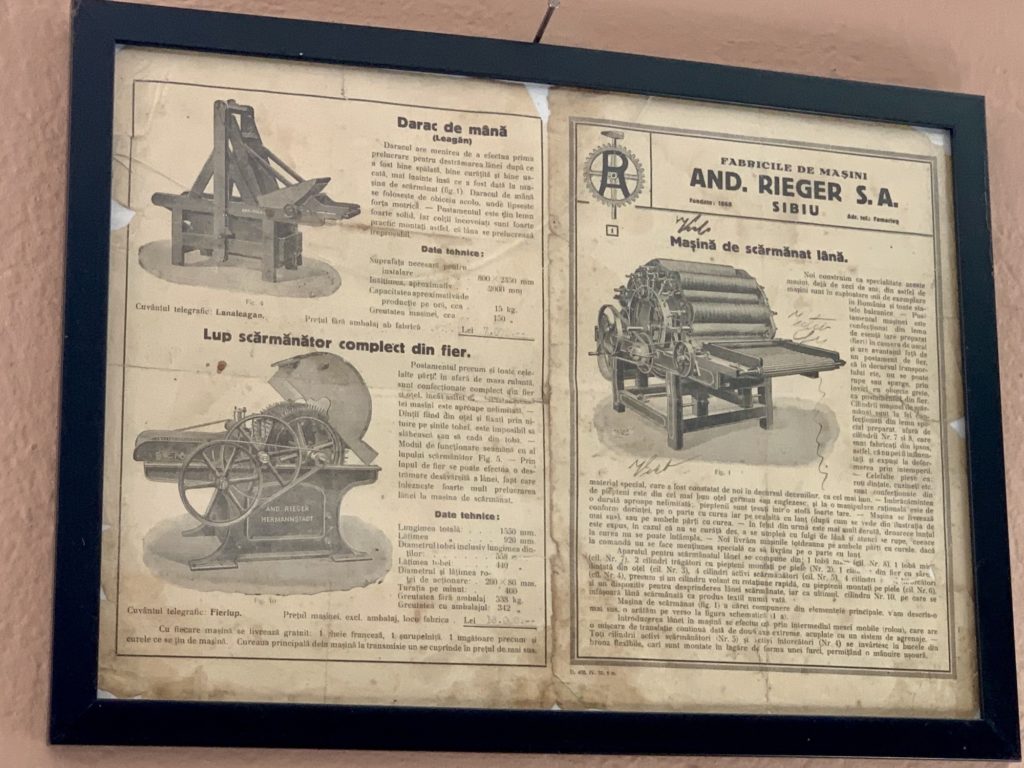

Next, we cross over the stream to another building where we see some heavy machinery reminiscent of factory work. These machines make the sheared wool of sheep into usable threads by going through several steps. The first machine separates the wool into thin fleece, which accumulates into many layers on the other end of the machine. The next station picks the thin layers off the fleece package and separates them into strands of wool. These wool strands are still weak, the thread has no tensile strength and just pulls apart, so they go into the next machine, which twists them into usable threads and rolls them onto spindles. The lady of the house also shows us some equipment that was used by hand for this process, and she tells us stories about her grandmother, who still did it that way and was very skilled at it. But automation made the processing of wool much more productive.

In the final room, we see balls of wool in different colours, and the host tells us how they were naturally dyed (for example with the skins of red onions), or mixed with synthetic threads to create different textures and colours. We also see another loom with a rug in the process of being made. They are manufactured on commission and by the meter. At the end of the tour, we go to the shop where we see some of this same kind of rug for sale, along with other textiles and a funny wool man.

We go exploring the outside by ourselves a little after the tour, enjoy the sunshine, and admire this truly idyllic countryside. What a lovely outing.

Wow really interesting to see how they actual still managed to get things done!

C

Thanks for sharing Dee such a beautiful interesting snapshot reminder of past processes & history, definitely a classic step back into rustic times just imagine the Millennials or Gen zed having to survive in these times? I think not 🙂